Oslo-based ONiO has raised €5 million to ramp manufacturing of ONiO.zero – the primary general-purpose microcontroller unit (MCU) that cold-starts from below 1µW and runs completely on ambient power.

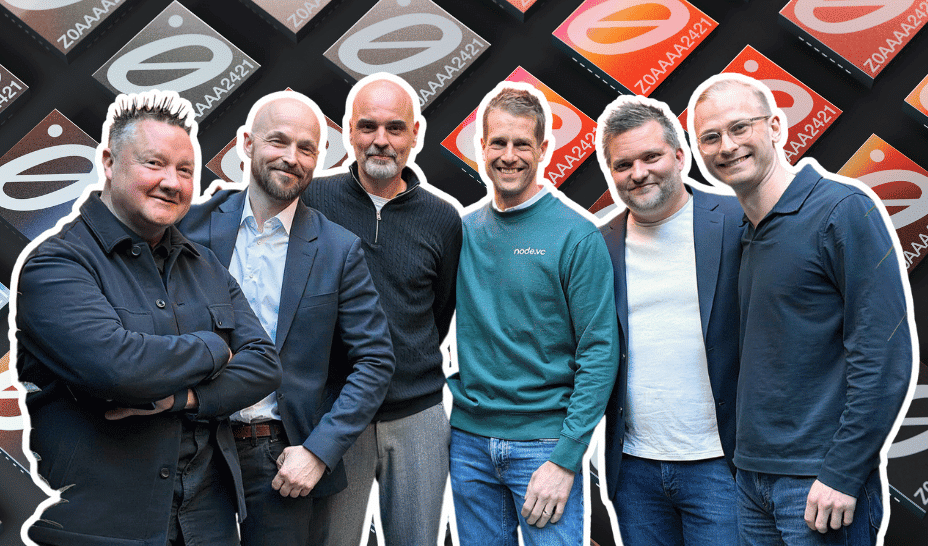

The spherical was led by Stockholm-based node.vc, with Helsinki’s Maki.vc as co-lead. Current buyers EIC Fund and MP Pension matched the funding and doubled down.

“ONiO represents the sort of breakthrough know-how we search for at node.vc,” stated Mårten Skogö, Companion at node.vc. “Their potential to energy a microcontroller completely from ambient power will not be solely technically spectacular – it’s essentially altering how we take into consideration sustainable IoT. The staff has confirmed that the know-how works in real-world functions, and now it’s time to scale. We’re excited to help ONiO as they bring about this game-changing chip to market.”

Based in 2016, ONiO is a fabless IoT firm specialising in ultra-low-power microcontrollers, together with the “world’s most power-efficient” MCU. Designed to harness ambient power, ONiO.zero operates on as little as 22µW/MHz.

The funding accelerates quantity manufacturing of ONiO.zero – their power-agnostic wi-fi microcontroller that cold-starts from lower than 1µW and runs on ambient power. Photo voltaic, RF, thermal, piezo – it apparently harvests no matter you throw at it.

No batteries required, although “it’s glad to collaborate properly with them when wanted“.

The core mission with ONiO was to stem the huge move of thousands and thousands of batteries into oceans and landfills, in addition to empower producers with minimalist, user-friendly, and cost-effective energy options. By unshackling IoT gadgets from conventional energy constraints, ONiO seems to drive a brand new period of innovation and sustainability within the IoT area.

The corporate says that all the pieces lives on a single die: A RISC-V CPU, radios, energy administration, safety, reminiscence and far more. They’ve built-in what used to take dozens of elements into one chip. It’s been examined in photo voltaic keyboards, digital shelf labels, air high quality sensors, asset trackers, and soil sensors monitoring crops.

Now they’re scaling manufacturing alongside the dev kits and reference designs that allow engineers construct the designs that make sense for his or her functions.

“All that’s left to do is to make much more of those tremendous chips,” says the corporate.