When a producer considers implementing automation of their operations, one of many first questions that sometimes arises is: What’s the price of a cobot? At first look, this looks as if an easy inquiry, however the reply is much from easy. Including a cobot to your manufacturing line isn’t simply an expense—it’s a strategic funding in effectivity, consistency, and long-term financial savings.

The value varies primarily based on the mannequin and options, however with the proper grippers, software program, and setup, a cobot can remodel your operations. Understanding the complete value image helps you make an knowledgeable resolution and unlocks the true worth of automation. Let’s break it down so you may see how rapidly a cobot pays for itself.

As with many merchandise, the price of cobots varies broadly. This variability may be in comparison with one thing reminiscent of the worth of a automobile. Simply as a fundamental economic system automobile may be bought for a number of thousand {dollars}, whereas high-end luxurious fashions can value tens of 1000’s, cobots additionally are available in numerous value factors.

Usually talking, the price of a cobot arm can vary from as little as $15,000 for an entry-level Chinese language-made mannequin to upwards of $60,000 for top-of-the-line, high-quality fashions that boast superior reliability and superior options.

Nevertheless, a cobot arm by itself doesn’t do a lot. Simply as a automobile wants gas, upkeep, and a driver to function, a cobot wants extra elements to operate in an industrial setting. This results in a vital second consideration: the price of your entire cobot system, not simply the arm itself.

Cobot System Prices: What’s Included?

While you’re budgeting for automation, it’s vital to acknowledge that the cobot arm is just one a part of the equation. To actually get worth from the cobot, you’ll want extra parts, together with:

- Finish-Effector: That is the a part of the system that interacts with the product, reminiscent of a gripper or suction cup, and its value varies relying on the precise job.

- Integration & Setup: Relying in your manufacturing line, you might want to switch present methods (conveyors, air methods, electrical infrastructure) to accommodate the cobot.

- Software program & Programming: A cobot may require customized programming to operate in your particular setting, or, in some circumstances, you might want a specialised interface to assist the cobot work together together with your present methods.

When you’re choosing a turnkey system the place every thing is pre-packaged and able to go, the price of a cobot system may be fairly cheap.

Nevertheless, in case your software requires a extra custom-made answer, the associated fee can escalate rapidly. In these circumstances, the price of engineering experience and the time required to create a tailor-made system can drive the overall value a lot larger.

Customized Options Issues

One of many greatest elements that may improve the price of a cobot system is customized engineering. When you have a posh job that requires particular tooling or specialised modifications to your manufacturing line, you’ll must put money into engineers to design and implement the answer.

Engineering expertise, notably these skilled with automation methods, is in excessive demand and might come at a premium. Customized options additionally are likely to have longer lead instances, that means you’ll must plan forward for the potential delays in getting your system up and working. Moreover, customized methods may face reliability challenges since they typically incorporate distinctive elements that haven’t been mass-produced or totally examined over time.

That being stated, a customized answer could also be mandatory for sure duties, and in these circumstances, the elevated funding may yield precious enhancements in effectivity and productiveness.

Nevertheless, in case your job is comparatively easy, there are a lot of off-the-shelf methods that may do the job successfully, conserving prices down.

What’s the Actual Value of Automation?

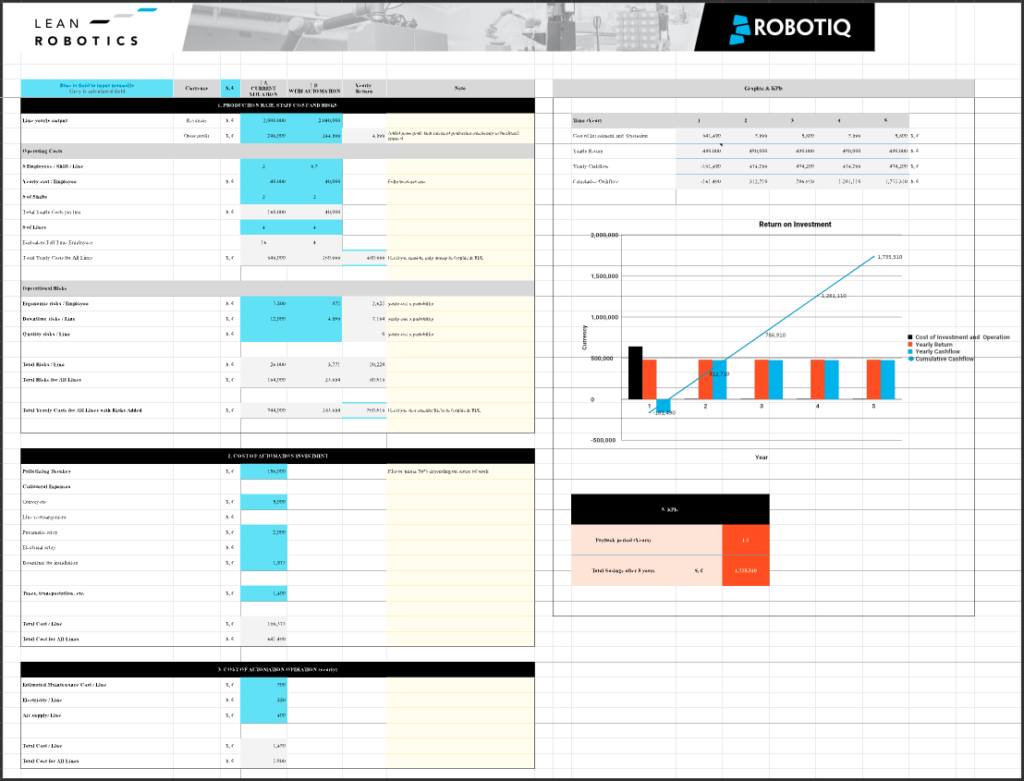

When contemplating the price of a cobot system, it’s important to give attention to the overall value of automation, which incorporates each the preliminary funding and ongoing operational bills. That is the place the idea of Return on Funding (ROI) comes into play. ROI is the important thing metric that producers want to contemplate to evaluate whether or not the automation venture is well worth the funding.

To calculate ROI, you might want to doc the present value of working your manufacturing line or the precise job you propose to automate. This contains the labor prices related to working the road, such because the variety of workers wanted, their hourly wages, and another prices associated to the operation. You must also issue within the annual output of the road, each by way of income and gross revenue. This can present a baseline for evaluating the prices earlier than and after automation.

After you have the baseline, you may calculate the price of automation. This contains the price of the cobot system itself, in addition to any collateral bills reminiscent of line modifications, downtime, and extra infrastructure prices. You should utilize our Lean Robotics ROI calculator as a software to estimate the ROI of a cobot in your manufacturing unit ground.

The Payback Interval

Sometimes, corporations take a look at the payback interval over a five-year horizon. The payback interval is the time it’s going to take for the financial savings generated by the cobot system to equal the preliminary funding.

For instance, some producers have seen excessive ROI circumstances, reminiscent of a vaccine producer who recovered a $200,000 funding in simply two months. Whereas that is an distinctive case, it illustrates the potential for speedy returns when the system allows important will increase in manufacturing output or when gross margins are excessive.

The Value of Inaction

Whereas calculating ROI is vital, producers additionally want to contemplate the price of inaction. When you determine to not put money into cobot automation, you might proceed going through rising labor prices, rising manufacturing prices, and potential challenges with assembly buyer demand. The price of not automating can eat into your margins over time as labor turns into costlier, and also you’re much less productive than your opponents who’ve adopted automation.

In lots of industries, the strain to cut back prices and improve output is simply rising. As labor shortages and financial challenges persist, the choice to automate turns into extra pressing. By investing in cobots now, you’re securing your future competitiveness in an more and more automated world.

The Hidden Advantages of Cobot Automation

Past the apparent monetary advantages, cobots additionally provide intangible benefits that may have a major impression on your enterprise. These embody:

- Reduced Ergonomic Risks: Cobot methods can tackle repetitive, bodily demanding duties, lowering the chance of damage to your employees and bettering office security.

- Worker Morale & Retention: By automating repetitive duties, you permit your workers to give attention to higher-value work, which may enhance job satisfaction and morale.

- Flexibility and Scalability: Cobot methods are extremely versatile and might simply be reprogrammed for brand spanking new duties or scaled to satisfy elevated demand. This makes them ultimate for companies that must adapt rapidly to altering market circumstances.

- Enhanced Buyer Notion: Many companies discover that clients respect seeing automation in motion, which alerts innovation and a forward-thinking method.

Able to put money into a cobot?

Talking with an knowledgeable can present precious insights to make sure you make the proper selections to your automation wants. Our consultants will help you assess your objectives, perceive the technical capabilities of cobots, and information you thru the method of choosing and integrating one of the best answer to your operations.