When demand surges, the very last thing you need is a bottleneck in manufacturing. That’s precisely what an electronics producer in Mexico Metropolis confronted—till they turned to automation. With labor shortages limiting output, they deployed Robotiq grippers to maintain up with orders, enhance effectivity, and enhance income. This wasn’t nearly reducing prices—it was about unlocking progress. See how they scaled smarter, quicker, and extra profitably.

Assembly the Challenges of Speedy Development

When an electronics producer in northwest Mexico Metropolis noticed a surge in demand, they confronted a well-known problem—easy methods to scale manufacturing whereas sustaining high quality and effectivity. Specializing in PCBs and liquid cooling units for automotive electronics, the corporate wanted to extend output however struggled with labor shortages.

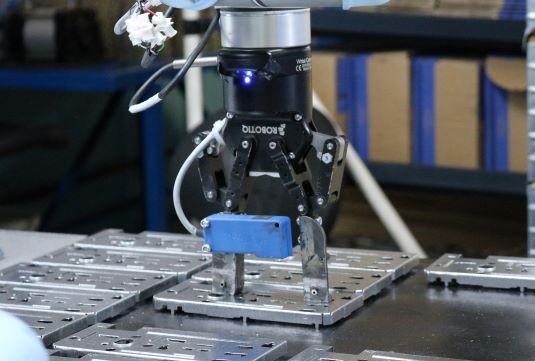

They turned to automation, investing closely in collaborative robots (cobots) to streamline their handbook meeting processes. Particularly, they wanted a dependable resolution for dealing with aluminum housings and different elements utilized in assembling communication modules. That’s the place Robotiq grippers got here into play.

Rethinking ROI: Extra Than Simply Labor Financial savings

Many corporations view automation strictly by the lens of labor value discount. However on this case, the ROI was much more compelling—automation not solely diminished dependency on handbook labor but additionally enabled elevated gross sales, improved gross margins, and better income. The quicker they automated, the faster they may capitalize on market demand.

With their cobot deployment, the producer carried out 24 Robotiq grippers throughout a number of meeting stations. The end result? A streamlined course of that improved effectivity, diminished errors, and ensured constant product high quality.

Questioning easy methods to calculate the ROI of a cobot in your manufacturing facility ground? Download the Lean Robotics ROI calculator.

Why Robotiq Grippers Have been the Proper Match

The producer wanted grippers that supplied:

- Precision: Their aluminum housings required correct dealing with, that means drive management and adaptive grip had been important.

- Flexibility: Not like customary open/shut grippers, Robotiq’s adaptive grippers allowed fine-tuned management, guaranteeing a safe however light grip.

- Ease of Use: The corporate’s operators shortly adopted the expertise, lowering integration time and maximizing uptime.

By leveraging a dual-gripper setup—one for loading supplies into machines and one other for transferring completed elements—the corporate considerably elevated throughput whereas sustaining consistency.

Of their case, they used a mix of Hand-E and 2F140 grippers

Recommendation for Electronics Producers Contemplating Automation

For different producers in automotive and IT electronics, right here’s what labored properly on this case:

- Have a look at confirmed functions: Many profitable automation tasks have already been carried out. Be taught from existing case studies and leverage finest practices.

- Suppose past fast prices: Whereas automation requires upfront funding, issue within the long-term positive aspects—greater effectivity, decrease defect charges, and elevated income potential.

- Use customary modules: Simplify the combination course of by selecting confirmed applied sciences and dealing with trusted automation companions.

- Begin sooner, profit quicker: The sooner you deploy automation, the earlier you begin seeing ROI. Maintaining issues easy with customary options helps shorten the payback interval.

This electronics producer made the good transfer of embracing cobots and Robotiq grippers to scale production. Their journey underscores the significance of considering past simply value financial savings—automation generally is a strategic enabler for progress, market responsiveness, and long-term success.

Should you’re dealing with related challenges, now is likely to be the best time to take that subsequent step.