It is a sponsored article delivered to you by COMSOL.

Pc modeling and simulation has been utilized in engineering for a lot of a long time. At this level, anybody working in R&D is prone to have both immediately used simulation software program or not directly used the outcomes generated by another person’s mannequin. However in enterprise and in life, “one of the best laid plans of mice and males can nonetheless go mistaken.” A mannequin is barely as helpful as it’s real looking, and typically the spec modifications at a tempo that’s tough to maintain up with or will not be absolutely recognized till later within the improvement course of.

Modeling and Simulation Is Nice, However…

One among my favourite elements about working at a multiphysics software company is attending to see up shut the entire intelligent and modern methods our clients use simulation to maneuver the world ahead. There was the loudspeaker engineer who talked about turning an thought of their head right into a viable product that handed each the technical spec and regarded good, and so they credited simulation for turbocharging their design iteration course of. One other time, I spoke with somebody who used our software program for automating their technique of designing boat landings for offshore wind generators by creating their very own library of elements, combining their discovered expertise with structural evaluation. Another person invited me into their spectacular check lab the place they confirmed off how they run experiments to generate materials knowledge, which they later used of their true-to-life laptop fashions.

The advantages of getting a preview of the real-world final result earlier than you decide to a mission plan or design transcend business and product choices. There are numerous examples of how modeling and simulation hurries up innovation and reduces total prices. That stated, utilizing simulation in the way in which it has largely been achieved over the previous 30 years has required particular experience and coaching on the right way to use the software program of selection. So whereas corporations that use it have quite a bit to achieve, the full acquire continues to be restricted by the variety of staff who’ve discovered the mandatory abilities to construct computational fashions. However that doesn’t have to be the case.

Bringing Simulation to Higher Heights By means of Customized Apps

Take an organization that develops energy transformer gear, as an example. Powering the grid entails transporting electrical energy over lengthy distances, which requires dangerously excessive voltages. To guard individuals in the neighborhood, transformers are positioned close to neighborhoods and buildings to lower the voltage upon arrival. Transformers are inherently noisy, however they are often designed to be as near silent as potential. As with most issues on this world, transformers contain many interconnected physics — electromagnetics, acoustics, and structural mechanics, on this case — which signifies that multiphysics simulation software program is the device for the job when optimizing their designs.

When organizations construct and distribute their very own customized simulation apps, everybody within the workforce will be capable of make selections based mostly on forecasts that account for real-world complexities and the underlying legal guidelines of physics.

The R&D engineers answerable for developing with one producer’s new transformer designs all knew the right way to use finite ingredient evaluation (FEA) software program, however they labored carefully with different groups and departments with out such experience. For instance, the designers tasked with constructing the ultimate transformers had no familiarity with FEA. As an alternative, they most well-liked to make use of spreadsheets and different instruments based mostly on statistics and empirical fashions, which labored effectively for transformers they construct incessantly, however not for brand new designs or situations the place completely different dimensions are launched. In that case, multiphysics simulation is totally essential to get correct predictions of how noisy the ultimate transformer might be. Moreover, if the ultimate design is just too noisy, the corporate has to make pricey modifications after the very fact. They wanted one thing higher.

What did they do? They constructed their very own custom simulation apps based mostly on the finite ingredient fashions. That means, their design crew may enter parameters into enter fields in a simple consumer interface — constructed by the engineers in-house, custom-made to swimsuit the corporate’s wants. Because the apps are powered by their very own underlying multiphysics fashions, the designers may then rapidly and precisely analyze how their transformers would hum on account of completely different combos of geometry, materials, and different design parameters.

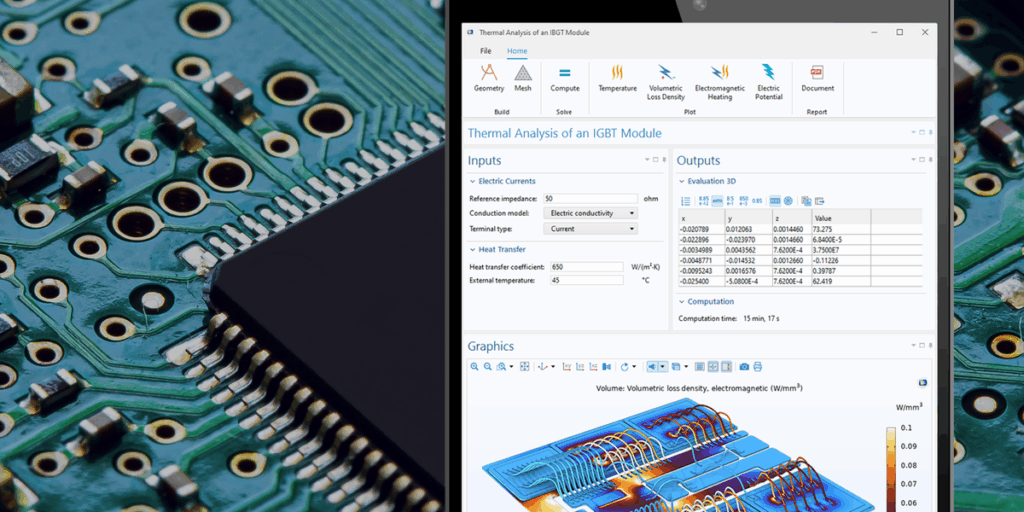

An instance of a customized app for creating high-voltage switchgears, the place the consumer inputs the voltage and the outcomes present the electrical potential and electrical area distribution based mostly on an underlying computational mannequin.COMSOL

Now, on this case, the apps had been constructed by and for R&D groups to enhance their very own work. Whereas this benefited the corporate and the crew, it’s nonetheless “simply” one other instance of utilizing modeling and simulation for R&D. Apps have the potential to interrupt far past the standard simulation software program consumer teams and we now have already began seeing actual examples of that.

Making Selections within the Subject, Manufacturing facility, and Lab

Even with correct design optimization by gear producers, the ability grid nonetheless must be monitored and maintained to stop and resolve outages and different points. With regards to energy cables, for instance, common well being checks are sometimes carried out by area technicians utilizing particular testing gear. Within the occasion of cable failure, the technicians are tasked with troubleshooting and pinpointing what prompted the failure. There are lots of elements at work: the atmosphere the place the cable is situated, cable construction and materials, impurities within the cable, voltage fluctuations, and working circumstances. The construction is especially advanced, comprising a number of layers and a wire core of mutually insulated stranded wires. Getting an in depth understanding of cable failure entails having the ability to analyze the within of the cables, which you are able to do utilizing simulation software program.

Nevertheless, it isn’t sensible or real looking to ship a simulation engineer out with the technicians neither is it real looking to show the technicians the right way to use simulation software program. But it surely is potential to have a simulation engineer construct a customized app for troubleshooting personnel to make use of out within the area. Simulation apps would permit them to evaluate cable failure based mostly on each physics and their native onsite circumstances and finally resolve the difficulty in actual time. This isn’t a fictional instance, by the way in which: an influence grid firm rolled out an app for this use a number of years in the past.

Customized simulation apps would permit area engineers to evaluate failures based mostly on each physics and their native onsite circumstances and finally resolve the difficulty in actual time.

Subsequent, let’s think about an organization targeted on manufacturing. An indoor atmosphere may be tightly managed, however there are nonetheless there are nonetheless many uncertainties at play that may influence manufacturing outcomes. Should you can predict them upfront, the enterprise might be higher off. Let’s take an additive manufacturing manufacturing facility producing elements by way of steel powder mattress fusion for instance. Again on the workplace, simulation engineers can optimize the designs forward of manufacturing, however the finish consequence may nonetheless not match the mannequin if the power circumstances are usually not superb on the time of manufacturing. Warmth and humidity inside the power could cause the steel powder to oxidize and choose up moisture whereas in storage, and this can alter the way it flows, melts, picks up electrical fees, and solidifies. Moreover, the powder is flammable and poisonous, much more so when it dries out. In different phrases, measuring and managing humidity ranges within the manufacturing facility impacts each product high quality and employee security.

One such firm modeled their very own manufacturing facility and constructed simulation apps round it to watch and predict manufacturing facility circumstances based mostly on variables resembling outdoors local weather, what number of machines are operating, and the way machines are positioned. Their workers can then use the apps on the spot to determine the right way to alter air flow and manufacturing schedules to create the circumstances they want for one of the best manufacturing outcomes.

A simulation app for predicting manufacturing facility circumstances.COMSOL

A simulation app for predicting manufacturing facility circumstances.COMSOL

Now, in case you are operating direct experiments in a lab or utilizing check rigs, you may, after all, see precisely what the actual final result is predicated on fastidiously chosen inputs and a managed setup. By coupling experimental testing with simulation, although, you may enhance understanding and make sooner predictions utilizing your lab-generated outcomes. For instance, in case you’re researching thermal elastohydrodynamic lubrication of drugs contacts, you may be taught by way of statement {that a} diamond-like carbon coating on the gears’ floor improves their effectivity, however that solely reveals you what occurs, not why.

On this case, having a simulation app within the lab would will let you simply enter the main points of your precise setup and get a multiphysics simulation of how the warmth flows contained in the system. A analysis crew that did precisely this, understood from the mannequin that the effectivity enchancment stemmed from the truth that the coating traps warmth within the contact, which lowers the lubricant’s viscosity and thereby decreases friction. They might not have recognized this utilizing solely the bare eye.

Simulation can be utilized as an efficient decision-making device within the workplace, area, manufacturing facility, and lab. When organizations construct and distribute their very own customized apps, everybody within the workforce will be capable of make selections based mostly on forecasts that account for real-world complexities and the underlying legal guidelines of physics — with out having to first discover ways to use simulation software program or take up lots of another person’s time. The world is ever altering and simulation apps assist corporations and groups of all types hold tempo.

Study extra about simulation apps on this steered useful resource: https://www.comsol.com/benefits/simulation-apps