Maintain chips flying!

Machine retailers usually function CNC machines at solely 60-70% capability, and there are a number of causes behind this. The dearth of expert operators is one issue. The manufacturing business faces main challenges, together with excessive job turnover charges of as much as 50% and a projected labor deficit of over 10% by 2030. The youthful technology’s disinterest in repetitive and low-skilled jobs contributes to this deficit. Discovering one good candidate is troublesome, however discovering a second candidate for a second shift is much more difficult. Discovering a candidate prepared to work night time shifts feels nearly like a miracle. However in immediately’s unsure financial local weather, with rising rates of interest and international instability, losing 30% of runtime is solely unaffordable.

Retrieve the remaining 30% promptly with a robotic machine tending answer

By using a robotic to produce elements persistently, the runtime of machines might be boosted by a minimal of 15%. This method not solely ensures extra dependable loading and unloading procedures but in addition eliminates the chance of human errors generally related to repetitive and monotonous duties.

In comparison with guide tending, using a CNC machine with a robotic system is 4 occasions cheaper. The Robotiq Machine Tending Resolution allows machine retailers to quickly recoup their funding in CNC machines.

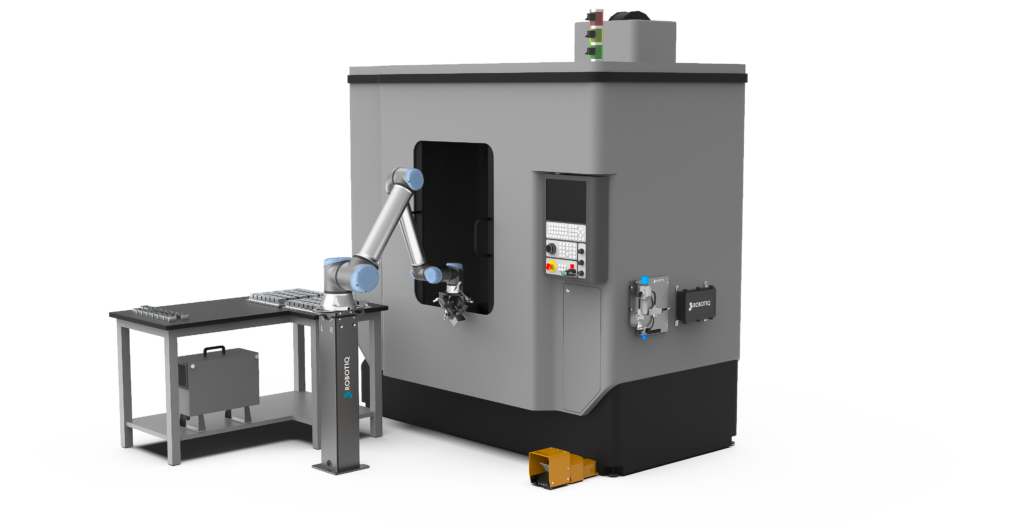

Meet the Machine Tending Resolution

Robotiq redefines automated half feeding with a non-invasive and streamlined collaborative robotic answer that empowers folks, boosts productiveness, and promotes adaptability, all whereas fostering a swift and cost-effective deployment.

The Robotiq Machine Tending Resolution replicates the actions of a human operator on a CNC machine. The system displays the machine’s standing by way of sign lights, opens and closes the chuck with a foot pedal, picks and aligns elements, and begins the machine with the press of a button. The robotic interfaces with the machine similar to an operator would however with out requiring communication playing cards, costly wiring, customized programming, or everlasting modifications. The answer doesn’t alter the CNC applications; exterior modules handle the communication between the CNC machine and the robotic.

-2.png?width=500&height=256&name=Machine%20Tending%20Solution_full%20cell_01%20(1)-2.png)

This non-invasive technique has a number of advantages.

- Appropriate with any CNC machine mannequin, model, or age, permitting producers to successfully automate their manufacturing ground.

- Standardized know-how that facilitates information switch and coaching.

- Deployment inside a couple of hours. There is no such thing as a manufacturing downtime.

- Non-invasive answer means you needn’t hack your CNC and danger voiding its guarantee.

- No complicated programming is required. Keep away from reliance on system integrators and guarantee steady manufacturing uptime even throughout changeovers.

- Seamless transition from automated to guide half feeding to simply handle small portions.

Preserve uptime with streamlined configurations

Machine tending functions are complicated. The movement required is intricate in an effort to keep away from collisions with the delicate machining tools. This complexity makes it troublesome for each inexperienced persons and skilled customers to program and redeploy shortly throughout changeovers. That’s the reason the Robotiq Machine Tending Copilot software program doesn’t require programming abilities. Configurations are grouped below assistant instruments designed to simplify setups and information customers by way of a sequence of steps. The configurations embody photos for visible steerage and to help the event of worker experience and autonomy.

Program Generator Characteristic

The Copilot software program takes the complexity out by producing program templates tailor-made to the CNC machine sort and gripper configurations. With a decade of experience in machine tending functions, Robotiq’s engineering workforce has developed complete options to automate the duty checklist creation course of in machine tending applications. This characteristic removes the necessity for customers to consider the logic and checklist of steps behind a machine program. After this system is routinely generated, the person merely must comply with the method and fill within the required data. Choose the CNC machine sort and gripper configuration to effortlessly unlock a program template.

Good Transfer Characteristic

Instructing trajectories to the robotic is fast with the Robotiq Machine Tending Good Transfer characteristic. Train as much as 10 waypoints and set a secure “fly zone” by manually shifting the robotic to every place. Producing optimized robotic motions with out collisions is completed in minutes and with out the necessity for programming. Non-robot consultants can effortlessly and confidently train the robotic and construct dependable applications.

Manually transfer the robotic to the specified place.

.png?width=603&height=393&name=photo%20(2).png)

|

New to the Robotiq Machine Tending Resolution |

Empower your workforce

Relying on skilled operators to feed parts to machines fails to optimize their unique strengths. Research shows that 83% of workers prefer employers who provide modern devices like robots to enhance their tasks. The Robotiq Machine Tending Solution has made automation accessible to businesses of all sizes, overturning the belief that it is too complicated. By redirecting skilled workers to more strategic tasks, machine shop owners can gain important competitive advantages, particularly when talent retention is a global challenge.

See how Fusion OEM empowered their workforce and increased their production by 50% with our Machine Tending Solution.

Do not let a 30% production runtime increase go to waste. Discover the potential of Robotiq’s Machine Tending Solution in bridging the gap in workforce availability, especially for night shifts and repetitive tasks. Embrace this opportunity to maximize your production runtime and stay ahead in the current economic landscape. Click here to transform your operations!