In manufacturing, effectivity isn’t nearly maintaining—it’s about staying forward. One in all our clients, a packaging producer serving grocery and bakery industries, lately took an enormous step ahead by upgrading their palletizing automation. Their journey affords nice insights for any producer trying to scale intelligently.

From Customized to Commonplace: A Smarter Transfer

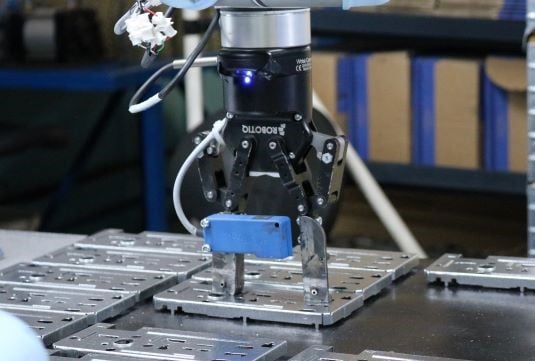

This firm had already dipped their toes into automation with a UR16-based {custom} palletizer. It labored, however they noticed the potential for extra—extra throughput, extra flexibility, and extra standardization. By upgrading to the UR20 with our PE20 answer, they unlocked new capabilities that made an enormous distinction.

Their reasoning? The meals and beverage business evolves continually, with packaging necessities shifting to satisfy shopper calls for. Their manufacturing staff wanted automation that might adapt simply as rapidly. The UR20’s prolonged payload and attain allow them to deal with a greater variety of SKUs, making their operations way more agile.

Past Labor Financial savings: The Actual ROI

Many corporations justify automation by chopping labor prices, however on this case, the first driver was scalability. They already had automation; they only wanted higher automation. The funding in a extra superior palletizer wasn’t nearly changing employees—it was about rising output, standardizing operations throughout a number of services, and making future rollouts simpler.

That’s a key lesson for producers: ROI isn’t nearly direct price financial savings—it’s about long-term agility.

Questioning the right way to calculate the ROI of a cobot in your manufacturing unit ground? Download the Lean Robotics ROI calculator.

Standardization: The Secret to Scaling Up

A significant purpose for this buyer was to standardize their palletizing course of throughout a number of areas. Their earlier setup labored, however it was a one-off answer. By selecting a standardized, productized system, they decreased complexity when deploying at new services.

This shift solves a standard downside: experience bottlenecks. When automation is custom-built for a single website, enlargement turns into tough as a result of the unique knowledgeable isn’t at all times there to help new areas. A standardized strategy makes onboarding and upkeep a lot smoother.

A Smarter Method to Automation Deployment

For corporations rolling out automation throughout a number of websites, prioritization is vital. One in all our different clients took a sensible, phased strategy:

- Begin with the simplest deployment – Choose the best software with the least changeover to get an early win.

- Increase primarily based on learnings – As soon as the primary deployment succeeds, transfer to extra complicated traces.

- Scale confidently – A step-by-step strategy reduces danger, optimizes funding, and builds momentum.

Surprising Wins

One stunning profit our buyer skilled? Elevated manufacturing effectivity. They initially noticed automation as a strategy to cut back guide work, however after implementation, they realized they’d been bottlenecked on the palletizing stage all alongside. Eradicating that bottleneck led to raised throughput throughout the board—an ROI enhance they hadn’t even anticipated.

Trying Forward

For producers contemplating automation, the important thing takeaways are clear:

- Suppose past labor financial savings. Take into account how automation can develop your capability and adaptability.

- Standardization is your buddy. A scalable answer simplifies deployment throughout a number of websites.

- Take a phased strategy. Begin with the best purposes and construct from there.

- And most significantly—don’t go it alone. Firms like Robotiq specialise in serving to producers navigate these choices, guaranteeing that each step provides worth to the larger image.

Wish to make automation give you the results you want? Let’s speak.