Automation refers to the usage of know-how to finish duties and processes with minimal human intervention. The time period encompasses a variety of applied sciences from robotic palletizing cells to AI product administration instruments. Automation is remodeling industries and there are large advantages to automating components of your small business.

The case for automation is getting stronger yearly. Whereas 10 years in the past, we have been nonetheless introducing firms to the essential advantages of automating even one course of, now individuals typically come to us already understanding that they wish to automate. They usually wish to do it shortly and effectively.

There are a lot of advantages to including automation, notably with robotics. Whereas quite a lot of discussions concentrate on the “easy advantages” of automation — like elevated effectivity, productiveness, and efficiency — there are various extra nuanced advantages to automation.

If you’d like your small business to thrive this 12 months, it is vital to know the precise advantages which can be most vital proper now. It is also vital to know what you need to keep away from when automating, to flee frequent pitfalls.

Let’s discover 9 of the highest advantages of automation in 2025.

9 Advantages of Automation in 2025 (and What to Keep away from)

1. Flexibility and agility

With robotic automation, we frequently speak about flexibility and agility. These are each advantages that include automation however one is more and more extra related in 2025…

Versatile automation refers to programs that may meet deliberate adjustments to process or product calls for. For instance, your organization would possibly expertise seasonal manufacturing spikes. A versatile automation course of can adapt to those predictable adjustments.

As Robotiq R&D Mission Supervisor, Nicolas Lauzier highlights, this agility and related good know-how may give your organization a aggressive edge:

“There may be an urgency for adopting automated options within the present financial local weather. In line with experiences, good manufacturing unit options would be the main drivers of competitiveness within the subsequent 5 years.”

A pitfall to keep away from right here is investing too closely in inflexible automation options. These are sometimes designed for mass manufacturing and might fall quick in in the present day’s fast-evolving markets.

2. Scale simply and adapt to alter

A standout advantage of automation is scalability. Not solely can the correct automation assist you to ramp up manufacturing to satisfy your strategic development targets, agile automation may also assist you to pivot manufacturing to handle sudden market shifts.

Throughout the Covid-19 pandemic of 2020, we noticed that many firms that succeeded in adapting to the altering world scenario had invested in the correct automation earlier than the pandemic.

One technique that may be very helpful is to deploy “copy-paste” robotic cells. This entails deploying a specific software as soon as after which replicating that very same cell to scale manufacturing.

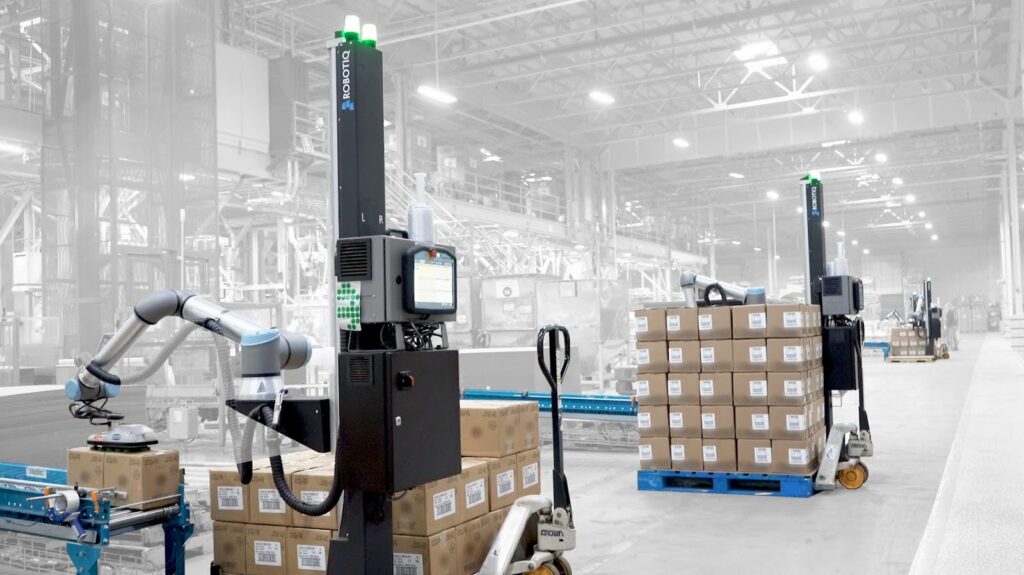

An instance of copy-paste automation is in decentralized palletizing. This modular strategy entails including a palletizing cell to the top of every new manufacturing line. By incorporating this core end-of-line course of into the road itself, you keep away from needing a drastic reconfiguration of your facility each time you scale manufacturing.

A pitfall to keep away from right here is assuming that what the market will need sooner or later or relying an excessive amount of on predictions. As a substitute, spend money on automation that may mean you can adapt to adjustments shortly once they occur.

3. Scale manufacturing regionally

Native manufacturing, empowered by collaborative robotic automation, is more and more thought of a strategic selection for producers.

For a few years, offshoring manufacturing was seen as the best way to scale manufacturing. Nevertheless, in recent times, reshoring production has turn into widespread. This shift is not only a pattern however is changing into a necessity within the quickly altering financial and geopolitical panorama.

By bringing manufacturing nearer to dwelling, producers can expertise many advantages, together with diminished transport prices, shorter lead instances, and the flexibility to customise merchandise for native markets.

Reshoring with robotic automation additionally builds resilience into an organization’s operations by lowering reliance on complicated world provide adjustments.

A pitfall to keep away from with reshoring is to match solely the preliminary prices reasonably than calculating the return on funding of automation in the long run. Offshored operations typically depend on low-cost labor, which may make automated options look extra pricey at first. Nevertheless, financial savings typically turn into clear if you mission into the medium to long run.

4. Make higher selections with knowledge

Automation would not simply carry out key duties in your small business, it additionally generates invaluable knowledge. This knowledge can feed into your wider enterprise analytics and assist you to make higher, extra strategic decisions.

Within the trendy world, knowledge is important for making good enterprise selections. With a robotic system, for instance, you’ll be able to generate knowledge that means that you can preserve optimizing your robotic deployment and enhance efficiency.

Our eBook Analytics for Cobots highlights how collaborative robots can simplify capturing this important knowledge. By monitoring solely the correct metrics, you’ll be able to concentrate on people who instantly align along with your operational wants for the automated resolution.

Gathering this knowledge may also assist you to justify your previous selections, resembling investing in automation within the first place. For instance, the info you gather from a collaborative robotic might help you calculate the ROI and make selections about future automation tasks.

A pitfall to keep away from right here is monitoring pointless knowledge. Solely monitor and analyze knowledge that’s related to your wants and software.

5. Solves workforce shortages

Labor scarcity is a rising problem in trendy manufacturing and is an issue we’ve got been monitoring for a number of years. With an ageing workforce and fewer expert employees in key jobs (resembling end of line palletizing), automation is more and more the one possibility for some firms.

Robotiq’s Nicholas Lauzier emphasizes the urgency of this case in 2024, stating:

“Research present that the labor scarcity producers at the moment face isn’t prone to diminish; in reality, it’s anticipated to worsen. As individuals retire, youthful employees more and more go for jobs with higher working circumstances and compensation, steering clear of producing positions.”

Automation presents a strategic response to this situation, enabling you to maximise the potential of your present groups. By permitting automated programs to take over the extra repetitive, mundane duties, you release your expert professionals for higher-value, extra intellectually stimulating actions.

A pitfall to keep away from isn’t speaking the labor shortages to groups earlier than including automation. When individuals perceive why you might be including this new know-how, they’ll extra simply get on board.

6. Construct safer, higher workplaces

One of the vital understated advantages of automation is its capability to create higher workplaces. By addressing the “4 D’s of robotics” you take away the least interesting points of individuals’s jobs.

These 4 D’s consult with duties which can be uninteresting, harmful, soiled, or pricey. They’re often jobs that result in low morale, larger accident charges, decrease job high quality, and elevated operational prices. By automating them, you’ll be able to take away the burden on human employees and make their jobs extra rewarding.

Robots typically excel on the duties that people do not get pleasure from doing. For instance, a uninteresting job may be a repetitive meeting process. When human employees do the identical process for hours on finish, they’ll turn into demotivated, and the duty high quality is diminished. However a robotic will simply and constantly carry out the identical process for hours on finish.

A pitfall to keep away from right here isn’t involving your group members within the deployment. Whenever you contain individuals from the beginning, they typically take possession of the robotic deployment, main to raised outcomes.

7. Minimize waste and enhance sustainability

Sustainability has turn into a central focus throughout many industries. As many firms look to align their operations with extra sustainable practices, automation can present a strong device to information this transformation.

Robotic automation, for instance, has been proven to make packaging processes extra sustainable. Packaging is usually a notoriously wasteful manufacturing stage, each in supplies and power utilization. With the correct automation resolution, you’ll be able to sort out this downside and contribute to enhancing your organization’s general sustainability.

By including collaborative robotic packaging, you’ll be able to optimize your workflow and lower materials use to a minimal. For instance, by monitoring your robotic, you’ll be able to tweak and modify the quantity of fabric utilized in packaging to chop it to a minimal. This isn’t a one-off exercise however reasonably a step you need to revisit sometimes to see how one can additional scale back waste.

A pitfall to keep away from at this stage is your automated processes in isolation. Typically, you’ll be able to scale back waste considerably throughout robotic deployment by noticing different inefficiencies in the remainder of your operations.

8. Guarantee constant operations

Whereas robotic automation is commonly most celebrated for enhancing effectivity and productiveness, maybe its most transformational profit is consistency.

In contrast to guide processes, automation is very constant. That is essential in enterprise processes because it ensures your organization is dependable and maintains a excessive stage of product high quality. Including a robotic to your manufacturing workflow not solely makes its particular process extra constant, it additionally improves the consistency of your whole manufacturing move.

In Eli Goldratt’s seminal guide “The Aim”, the writer highlights how a specific robotic workstation units the work cadence for the remainder of the manufacturing, serving to to take away a problematic bottleneck. Folks working in manufacturing typically speak about how the robotic makes them extra constant as a result of they wish to “beat the robotic” or sustain with its constant throughput.

Lean Robotics offers a targeted pathway that may assist obtain this consistency in your small business. The primary stage, mapping your present guide course of, can typically assist you to determine wasteful or inconsistent steps earlier than you automate with a robotic.

A pitfall to keep away from right here is making an attempt to suit your automation into your course of with out contemplating the remainder of your manufacturing phases.

9. Automation is less complicated than ever

Maybe the most important profit to utilizing automation in 2025 is how straightforward it’s now to automate in comparison with the way it was up to now.

Once we first began serving to firms to automate their processes, they nonetheless wanted to place in numerous work throughout deployment. Lately, including a robotic to your manufacturing is less complicated than ever earlier than.

Robotiq’s CEO Samuel Bouchard highlighted this at a Automatica trade fair, saying:

“With plug-and-play parts, you continue to have to do a little bit of the mixing. Our early adopters have been keen to try this. Now we’re working with individuals who do not even know what a cobot is. It permits extra individuals to undertake robots into their factories.”

With options like software kits you’ll be able to add robotics to your course of shortly and simply, serving to you to realize the outcomes you wish to make.

By eradicating uninteresting, harmful, soiled, and pricey duties from the palms of people, you need to use automation to make the mark you wish to make on the world.

As Samuel says, that is a part of our core driver at Robotiq:

“Our mission for the previous 14 years has been to free human palms from repetitive duties. That is nonetheless our mission. We see quite a lot of cobots, however I nonetheless suppose we’re at a extremely early stage. There may be nonetheless quite a lot of potential.”

How will you automate in 2025?

Automation in 2025 guarantees a world past simply effectivity or productiveness.

From enhanced labor dynamics to sustainability, consistency, and usefulness, its advantages ripple throughout each facet of enterprise. Nevertheless, the important thing to reaping these rewards lies in making use of that automation thoughtfully and avoiding key pitfalls.

What is going to the way forward for automation seem like in your organization?

Take a look at our application kits to see how simply you’ll be able to apply automation this 12 months.

What profit most speaks to your wants proper now? Inform us within the feedback beneath or be a part of the dialogue on LinkedIn or Facebook.